SOURCING

We have a team dedicated to finding the perfect fabric or trim for your product. We have built relationships with suppliers all over the world.

PATTERN

We have the ability to create patterns from scratch. First pattern style development, grading, production pattern creation, production markers and digitizing of paper patterns.

SAMPLING

Sampling is the product development and one of the most important stages of the whole process. The sampled garments represent the accuracy of the patterns and quality of production skills and techniques.

PRODUCTION

All stages of our production are monitored via our latest technology, to ensure a smooth process-flow. We maintain constant quality control at each stage of production. From scratch to final product, we regularly examine the effectiveness of our processes and workflows.

CUTTING

Automatic spreading machine allows spreading of a full range of available fabrics: from very delicate, thin, elastic and difficult to spread, to thick, heavy fabrics.

Automatic Cutting: The lay is cut automatically via our latest technology automatic Cutter system.

SEWING

Poti Textile has 14 production lines in house, with annual capacity of 7,000,000 pieces.

The sorted bundles of cut parts are send from the cutting department to production line where Sewing is done. Sewing lines provide continuous process flow within a single line to include sewing, ironing and quality control.

Visual displays at the end of lines show the performance of each line.

AUTOMATION

Poti Textile has acquired the latest technology machinery which ensures the maximum process automation in the modern garment production industry.

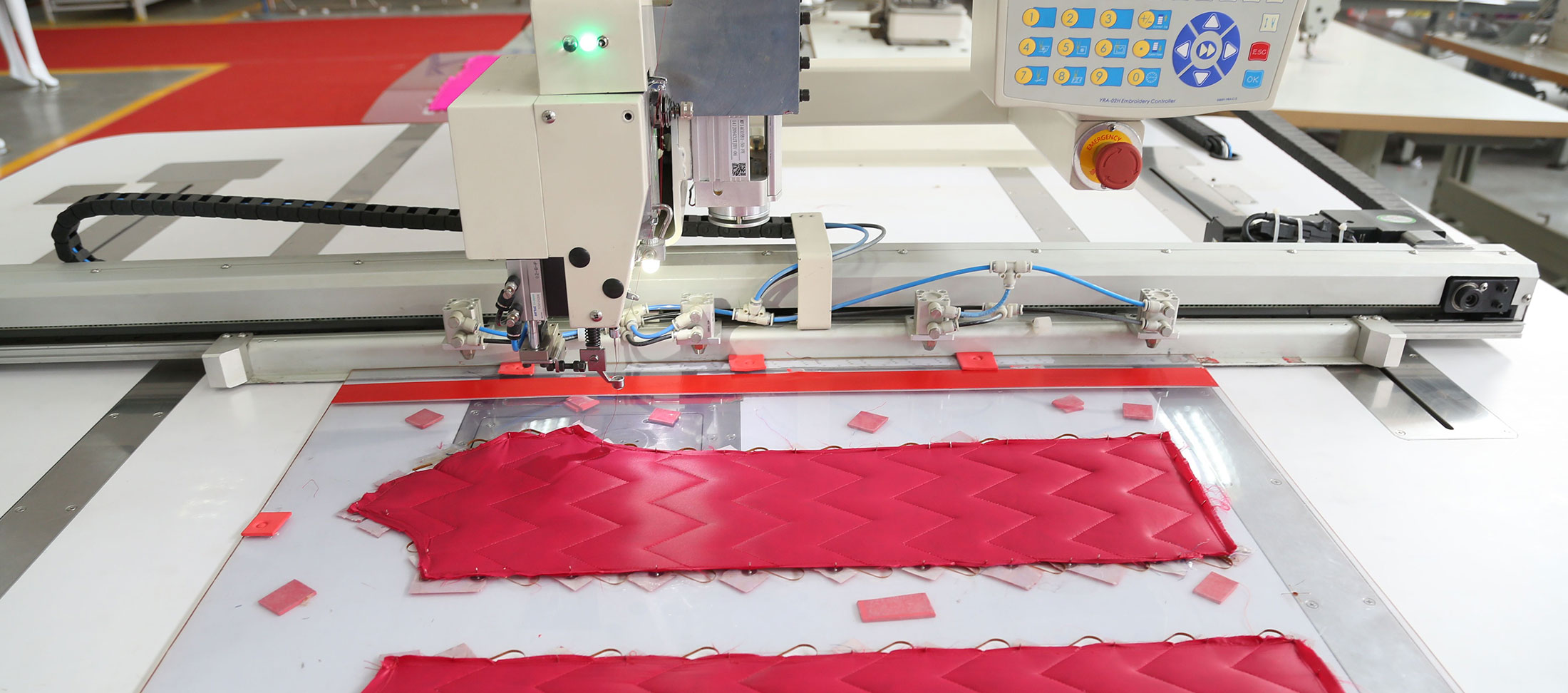

EMBROIDERY

Multi-function embroidery machine, a generous embroidery area, and a crosshair embroidery laser with precision accuracy. Its quick set up and fast multi-needle embroidery enables to embroider large multi-colored designs with minimum thread changes and greatly increased productivity.

PACKING

The finished garments from sewing lines are packed and scanned by metal detectors. Goods are boxed in the metal free zone. Automatic packing machinery ensures high-quality packaging and saving time.